Extrusion

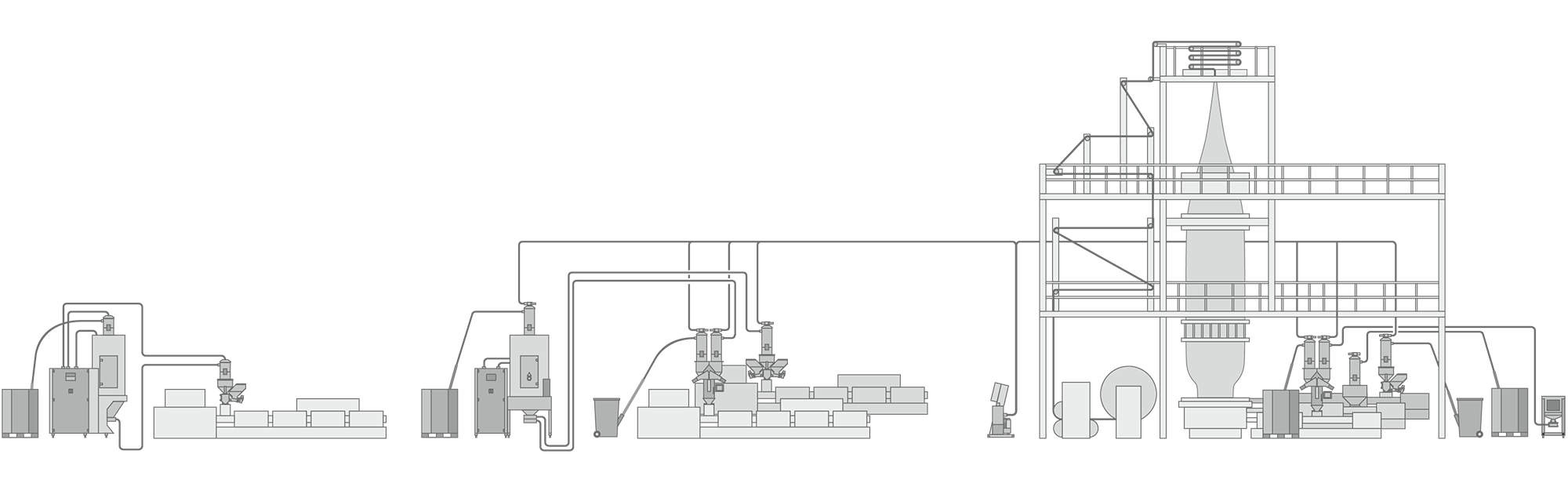

For foil, fibre, pipes and profiles, cables.

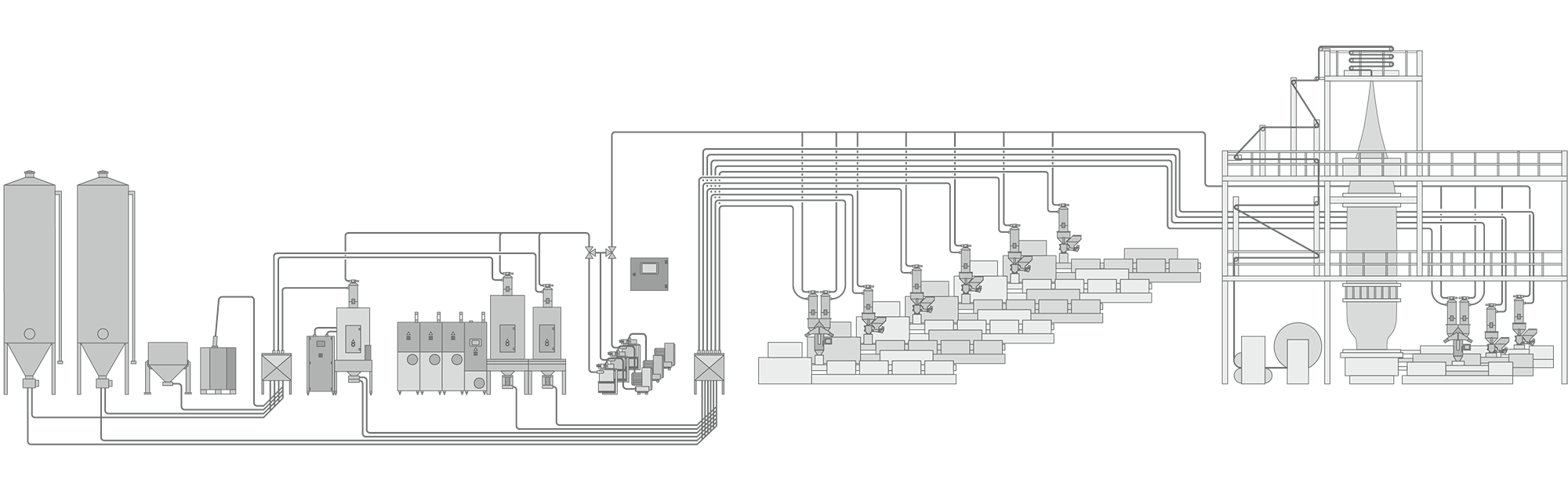

For sheet, pipes and profiles.

Extrusion is used to manufacture hoses, film, sheet or pipes with long lengths from plastic compounds (polymer materials or compounds). The plasticized material for this is continuously pressed through a die.

The process is continuous and has multiple steps. The raw material is placed in a cylinder where it is plasticized, homogenized and degassed using a screw. Usually single screws are used, but double screws can also be used. The plasticized mass is then pressed continuously through a die with a shaped opening (nozzle, template). This results in a continuous solid being produced in the shape of the opening. Afterwards, the extrudate is stabilized and cooled in this shape on a calibration and cooling line. As the process is theoretically endless, the finished product is cut to length at the end of the extrusion line. If the final product consists of multiple layers, multiple extruders are attached to one tool. This is called co-extrusion.