SPECTROCOLOR V

With the volumetric dosing and mixing station SPECTROCOLOR V, motan offers a simple solution for the economic production of plastics parts: precise dosing and homogeneous mixing with highest repeatability.

Our unique gravity-mixing principle offers you a high consistency of mix for all the components before they reach the extruder. This plays a key role in guaranteeing you perfect plasticization and homogenization of the materials.

SPECTROCOLOR V doses and mixes all easy to normal flowing granular materials. Up to six dosing modules, supports both flood-fed and starve-fed extrusion.

- ×

Volumetric

SPECTROCOLOR V

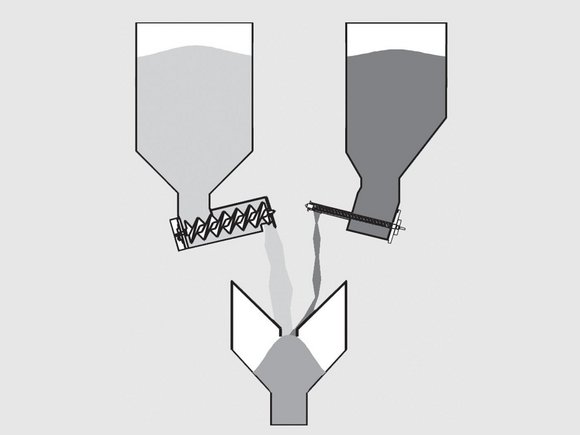

Gravity-mixing principle

Unbeatable mixing quality.Our unique gravity-mixing principle provides you a high level of mixing consistency without the need to mechanically mix. This plays a key role in achieving perfect plasticization and homogenization of the materials in the extruder.

Volumetric

SPECTROCOLOR V

Synchronous dosing

Better quality of end product and cost efficient because no over dosing of expensive materials.Synchronous dosing offers you excellent recipe accuracy and reproducibility, which can be followed at any time.

Volumetric

SPECTROCOLOR V

Compact design

Requires little space.Extremely compact construction due to the unique design of the supply hoppers. This allows you to install the station where many other similar units would not fit.

Volumetric

SPECTROCOLOR V

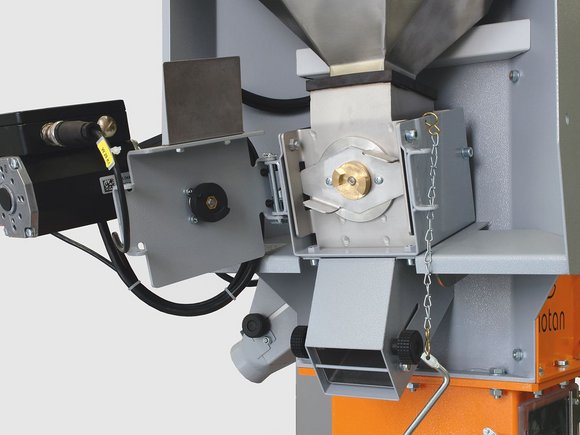

Dosing motors

Greater reliability because maintenance free.The dosing motors are swivel mounted and can be removed without tools. The motors are brushless and have integrated motor management which makes them maintenance free.

Volumetric

SPECTROCOLOR V

Angled dosing screws

Greater accuracy because no material slip.There are six different sizes of wear-resistant dosing screws available and they can be removed without the use of tools. The screws are inclined at an angle for a constant dosing flow insensitive to vibration. This gives you greater accuracy because machine movements have no effect on the dosing process and material slip on the screw is eliminated.

Volumetric

SPECTROCOLOR V

Quick material changeovers

Higher efficiency because more time spent in production.Cleaning and material changeovers are fast and require no tools. The quick-change system, compromised of a discharge slide gate for emptying materials, a removable supply hopper, a swivel mounted motor, and a dosing screw with a quick release connection, makes the unit easy to operate and saves you valuable time.

Volumetric

SPECTROCOLOR V

VOLUnet control

State-of-the-art control. Innovative, Ethernet-based open network architecture.Intuitive full colour graphic display with touch screen for hassle-free operation of SPECTROCOLOR V.

- Suitable for up to 6 dosing modules

- Up to 50 recipes can be stored

- Reporting function via Ethernet

- Standard network interface (Ethernet) for integration in the motan CONTROLnet network

- Convey control as option for METRO G material loaders and blowers; further options through inter-process communication.