MINICOLOR G

The demand for excellent mixing quality and consistently accurate dosing is a must when combining additives to the virgin material at the processing machine.

The gravimetric MINICOLOR G dosing and mixing units meet and exceed these requirements. Mounted at the feed throat of the plastics processing machine, the units require very little space.

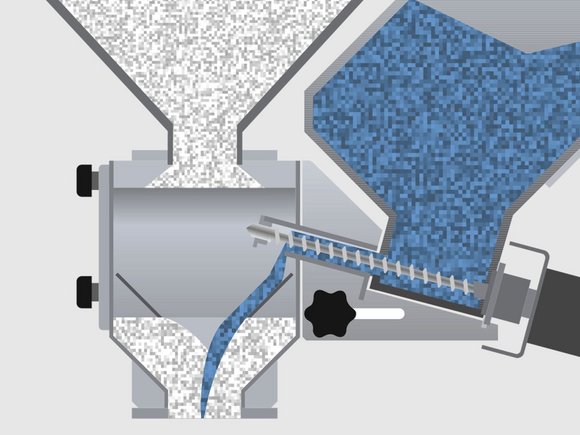

Depending on need and requirement, screw or disc dosing modules can be installed at the mixing neck. Disc dosing is ideal for translucent and opaque parts as well as for dosing very small quantities.

- ×

Gravimetric

MINICOLOR G

Fully gravimetric

Gravimetric guarantees and documents the amount of additive dosed.The dosing module sits on a robust but extremely precise load-cell and operates using loss-in-weight metering technology, giving you a high level of operational security as all parameters can be documented. The MINICOLOR G is insensitive to vibrations and is specially designed for mounting directly onto the feed throat of the processing machine.

Gravimetric

MINICOLOR G

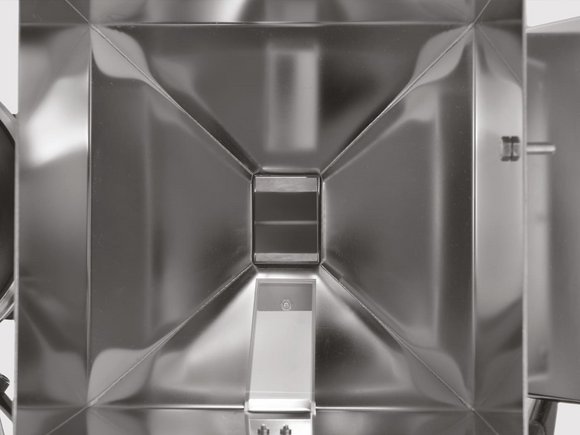

Mixing neck

Unbeatable mixing quality.The mixing cruciform is made of stainless steel. It separates the main material from the additives until they meet just above the throat of the processing machine. They then flow together, resulting in a homogeneous mix with no material separation.

Gravimetric

MINICOLOR G

Synchronous dosing

Better quality of end product and cost-efficient because no overdosing of expensive materials.Synchronous dosing provides excellent recipe accuracy and reproducibility which can be traced at any time. For example, you can check the actual dosed throughput and these values can be documented when using a MINICOLOR G.

Gravimetric

MINICOLOR G

Mounting flange

Easy to fit – no need for drilling.The mounting flange is designed so that it can easily be mounted on different sized feed throats without the need for drilling.

Gravimetric

MINICOLOR G

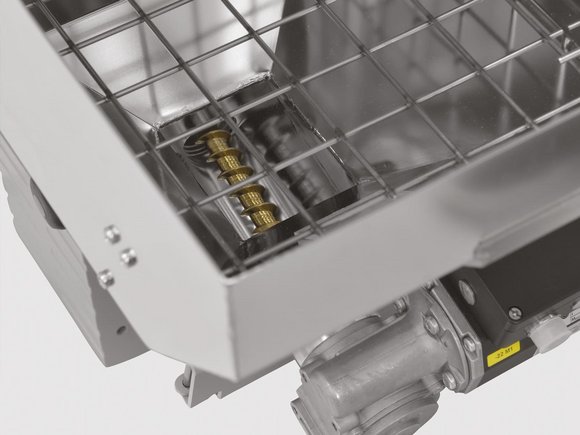

Angled dosing screws

Greater accuracy because no material slip.There are three different sizes of wear-resistant dosing screws available and they can be removed without the use of tools. The screws are inclined at an angle for a constant dosing flow insensitive to vibration. This gives you greater accuracy because machine movements have no effect on the dosing process and material slip on the screw is eliminated.

Gravimetric

MINICOLOR G

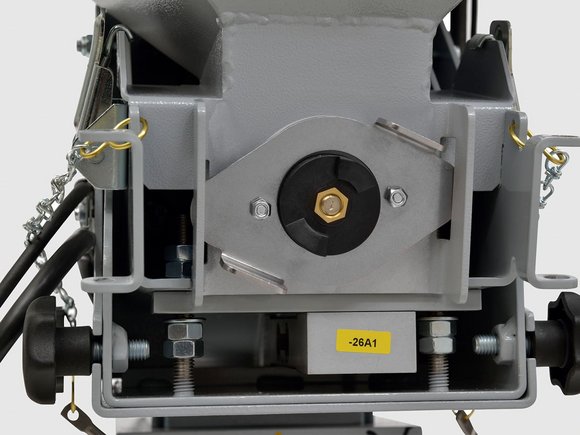

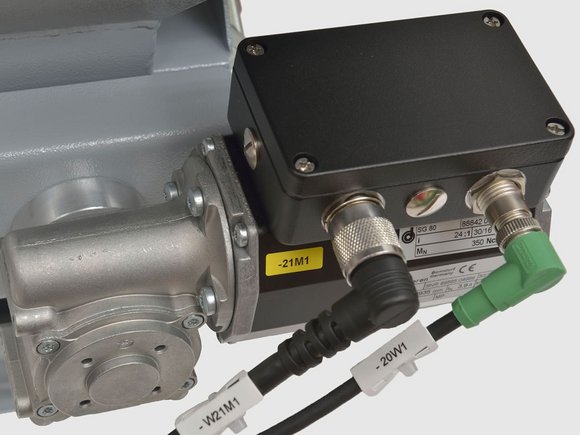

Dosing motors

Greater reliability because maintenance free.The dosing motors are swivel mounted and can be removed without tools. The motors are brushless and have integrated motor management which makes them maintenance free.

Gravimetric

MINICOLOR G

Simple calibration

Quick and easy with no material spillage.During calibration, you can easily withdraw the dosing module by loosening two star grips in order to collect and weigh the additive sample. This means you save time and there is no material spillage.

Gravimetric

MINICOLOR G

Quick material changeovers

Higher efficiency because more time spent in production.Cleaning and material changeovers are fast and require no tools. The quick-change system, a removable supply hopper, a swivel mounted motor, and a dosing screw with a quick release connection, makes the unit easy to operate and saves you valuable time. The complete dosing module can be used as a colour cassette, allowing you fast colour changes without any previous cleaning.

Gravimetric

MINICOLOR G

METRO VL G

Ensures that the supply hopper will not run empty.For automatic filling of the additive supply hopper of the MINICOLOR G you can use a compressed air loader. The loader can be installed by replacing the supply hopper lid. With METRO VL G the load cell signals the need for material and ensures that the hopper never runs empty.

Gravimetric

MINICOLOR G

GRAVInet MC control

Ensures that the supply hopper will not run emptyThe GRAVInet MC control system boasts innovative, Ethernet-based open network architecture. The full colour touchscreen gives you simple, intuitive, fast, and reliable operation. It has comprehensive features for process and recipe management, offering you reporting functionality for quality assurance and it delivers advanced service functions and graphical display of process data.

- Potential-free alarm output and external signal input (external contact) for the dosing cycle

- Storage of up to 50 recipes possible

- Detailed report function via Ethernet

- Automatic adjustment of masterbatch dosing depending on the regrind

- Unit with two dosing modules enables fast colour changes