Volumetric

sCOLOR V

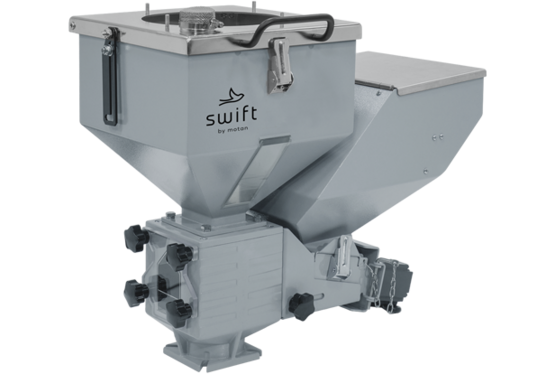

Combining additives with the virgin material at the processing machine requires excellent mixing quality and consistently accurate dosing. These requirements can be achieved and exceeded with the volumetric sCOLOR V dosing and mixing unit. The units are mounted at the feed throat of the plastics processing machine and are space-saving.

All advantages at a glance

Mixing neck

Synchronous dosing

Mounting flange

Angled dosing screws

Dosing motors

Simple calibration

Quick material changeovers

sCOLOR control

- ×

×

Volumetric

sCOLOR V

Mixing neck

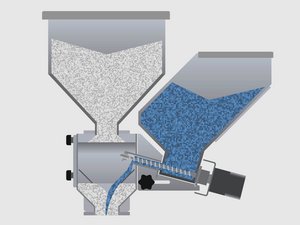

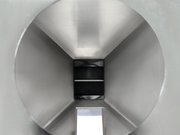

Excellent mixing qualityThe mixing cruciform is made of stainless steel. It separates the main material from the additives until they meet just above the throat of the processing machine. After flowing together, they result in a homogeneous mix with no material separation.

previous argument1 / 1next argument

×

Volumetric

sCOLOR V

Synchronous dosing

Only the right amount of material is ever dosed.Excellent recipe accuracy is achieved with synchronous dosing.

previous argument1 / 1next argument

×

Volumetric

sCOLOR V

Mounting flange

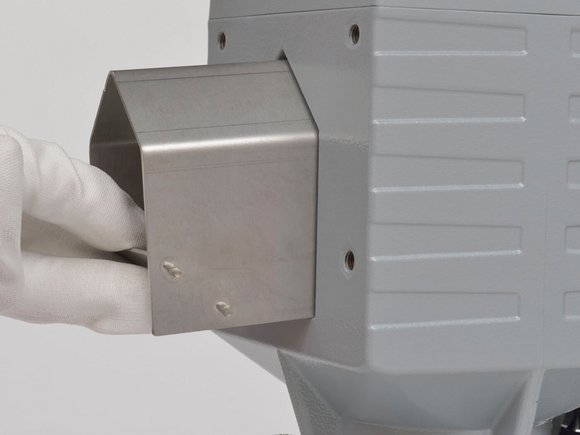

No need for drillingThanks to the user-friendly design of the mounting flange, fixing the unit on to different sized feed throats without the need for drilling is very easy.

previous argument1 / 1next argument

×

Volumetric

sCOLOR V

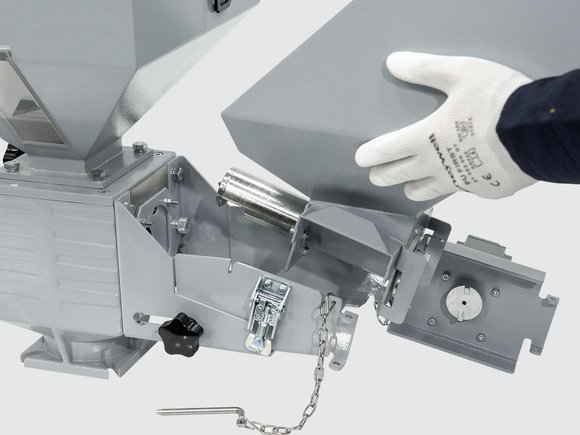

Angled dosing screws

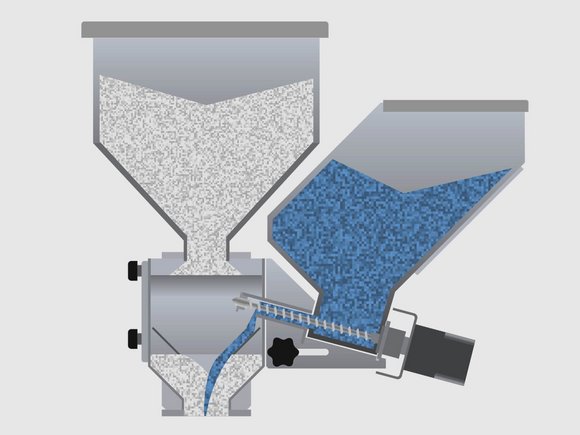

No material slip on the screw.The screws are inclined at an angle for a constant dosing flow insensitive to vibration. This gives you greater accuracy because machine movements have no effect on the dosing process and material slip on the screw is eliminated.

There are three different sizes of wear-resistant dosing screws available. They can be removed without the use of tools.

previous argument1 / 1next argument

×

Volumetric

sCOLOR V

Dosing motors

Maintenance free and reliableThe dosing motors are brushless which makes them maintenance-free. They are swivel mounted and can be removed without tools.

previous argument1 / 1next argument

×

Volumetric

sCOLOR V

Simple calibration

No material spillage during calibration.By loosening two star-grips, you can easily withdraw the dosing module in order to collect and weigh the additive sample during calibration. This means you save time and there is no material spillage.

previous argument1 / 1next argument

×

Volumetric

sCOLOR V

Quick material changeovers

Higher efficiency because more time spent in production.Material changeovers and cleaning are fast and require no tools. The unit is easy to operate and saves you valuable time because of the quick-change system, a removable supply hopper, a swivel mounted motor, and a dosing screw with a quick release connection. The complete dosing module can be used as a colour cassette, allowing you fast colour changes without any previous cleaning.

previous argument1 / 1next argument

×

Volumetric

sCOLOR V

sCOLOR control

Intuitive colour graphic display with touch screen for easy operation of sCOLOR V.The modern microprocessor control comes with 16 user interface languages. It is suitable for one or two dosing modules and has a user-friendly additive calibration wizard. The regrind compensation function ensures that only the necessary masterbatch is dosed.

previous argument1 / 1next argument