Gravimetric

sBLEND G

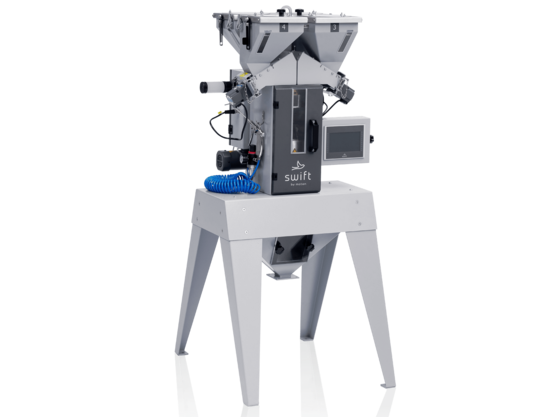

sBLEND G gain-in-weight dosing and mixing units accurately dose and mix up to four materials. These modular, gravimetric units are available in sizes 50, 130 and 300 with the largest unit having a total average throughput of up to 300 kg/h. The units operate with two different types of dosing: vertical slide valves for the main components and up to two screw feeders for high accuracy dosing of additives.

The sBLEND G is equipped with an advanced microprocessor control system. It can display and monitor throughput and provides calibration support. The sBLEND G can be operated locally or remotely via Ethernet.

All advantages at a glance

Gravimetric dosing

Slide valve dosing

Angled screw dosing

Modular design

Stainless steel

Quick material changes

Dosing motors

Weigh bin

Mixing chamber

Installation on the machine

sBLEND control

- ×

×

Gravimetric

sBLEND G

Gravimetric dosing

Absolutely true to recipe and reproducible.The high and consistent dosing accuracy of sBLEND G means that you can reduce the percentage of additives to be dosed without loss of quality, thus saving material and costs.

previous argument1 / 1next argument

×

Gravimetric

sBLEND G

Slide valve dosing

High accuracy.The main components (either virgin or regrind material) are dosed with a vertical slide valve. In this way, a high dosing accuracy is achieved. The slide valves are controlled by pneumatic cylinders.

previous argument1 / 1next argument

×

Gravimetric

sBLEND G

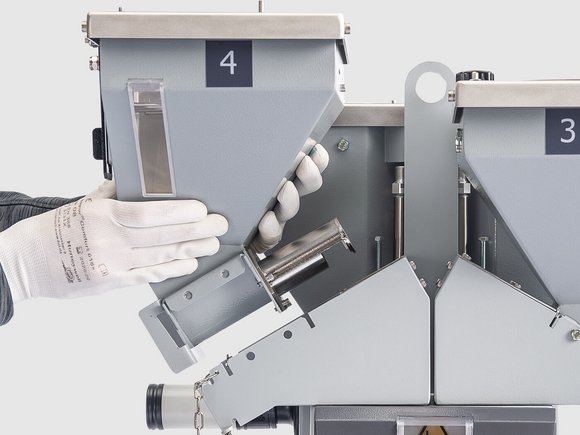

Angled screw dosing

Greater accuracy because no material slip.The screw dosing modules are available in two sizes and can be removed without tools. Additives are dosed into the weigh hopper via an angled feed auger. This reduces material slippage and prevents over-dosing of expensive additives, which in turn saves money.

previous argument1 / 1next argument

×

Gravimetric

sBLEND G

Modular design

Flexibility for individual applications.The sBLEND G is available with two slide valves as standard. The allocation of up to two additive components is flexible. Two different screw sizes are available.

previous argument1 / 1next argument

×

Gravimetric

sBLEND G

Stainless steel

Contamination free and easy to clean.All material contact parts are made of stainless steel. This ensures contamination free operation and easy cleaning due to the high-quality surface finish.

previous argument1 / 1next argument

×

Gravimetric

sBLEND G

Quick material changes

No tools required.Cleaning and material changes are quick and easy without the need for tools. The quick-change feed screw system, removable supply hopper, swivel-mounted motor and quick-release dosing screws are easy to clean. They make handling easier for the operator and thus reduce the time required. The complete dosing module can be used as a colour cassette, allowing you fast colour changes without any previous cleaning.

previous argument1 / 1next argument

×

Gravimetric

sBLEND G

Dosing motors

Greater reliability because maintenance free.The dosing motors are swivel mounted and can be removed without tools. The motors are brushless and have integrated motor management which makes them maintenance free.

previous argument1 / 1next argument

×

Gravimetric

sBLEND G

Weigh bin

Easy and quick handling.The weigh bin can be removed quickly and easily without the need for tools and can be cleaned away from the unit.

previous argument1 / 1next argument

×

Gravimetric

sBLEND G

Mixing chamber

Homogeneous mix.The bowl-shaped mixing chamber with its optimised agitator design creates a zone free of dead spots where the raw materials are evenly mixed. The design promotes uniform discharge to reduce material loss. The mixing chamber can be removed for cleaning quickly, easily and without tools.

previous argument1 / 1next argument

×

Gravimetric

sBLEND G

Installation on the machine

Saves you valuable floor space.The sBLEND G can be easily mounted on the throat of a processing machine. Material segregation is prevented because of the short distance the material travels from the sBLEND G mixing chamber to the machine throat.

Of course, the dosing and mixing unit can also be placed next to the machine or operate as a central station feeding multiple processing machines.

previous argument1 / 1next argument

×

Gravimetric

sBLEND G

sBLEND control

Modern microprocessor control.The sBLEND control unit is a state-of-the-art microprocessor control unit with an innovative, open network architecture based on Ethernet. This allows the sBLEND G to be operated directly at the machine or remotely.

The advanced 7" colour touch screen display is intuitive and easy to use for fast and safe operation. The controller can monitor and display throughput and provides calibration support. The material feed rate is automatically calculated based on the calibrated weight and formula.

previous argument1 / 1next argument