Granules

sCONVEY HOS

Cost-effective and efficient material conveying can be realized with sCONVEY HOS material loaders. This improves the overall process management of your system.

The plastic granules are transported quickly and cleanly into hoppers, drying bin or other dosing and mixing units and fed to the machine as required. This eliminates material wastage and keeps the work-space clean and safe.

All advantages at a glance

Polished stainless steel

Vacuum valve with implosion

Conical lid

Material inlet flap

Stable construction

Sieve filter

sCONMIX proportioning valve

Stainless steel discharge flap

Machine loader

Loader control box

Conveying control

- ×

×

Granules

sCONVEY HOS

Polished stainless steel

Easy cleaning and contamination free.All material loaders are made of polished stainless steel. The continuous hopper body with a high-quality surface allows contamination-free operation and quick and easy cleaning.

previous argument1 / 1next argument

×

Granules

sCONVEY HOS

Vacuum valve with implosion

Reduced maintenance costs and consistently stable material loading.After each conveying cycle the stainless-steel filter is automatically cleaned by implosion. This keeps the unit low-maintenance and safe in operation. Due to the vacuum, the conveying capacity remains stable and the unit remains dust-free.

previous argument1 / 1next argument

×

Granules

sCONVEY HOS

Conical lid

Improved aerodynamic effect.The conical shape of the hopper loader lid is better adapted to the vacuum valve. In combination with the vacuum valve directly above the sieve filter, the aerodynamic effect is improved. In addition, the conical shape avoids dead corners and provides greater dust collection capacity.

previous argument1 / 1next argument

×

Granules

sCONVEY HOS

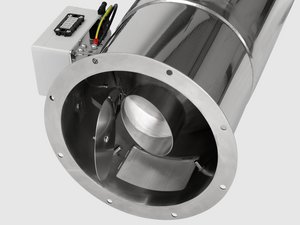

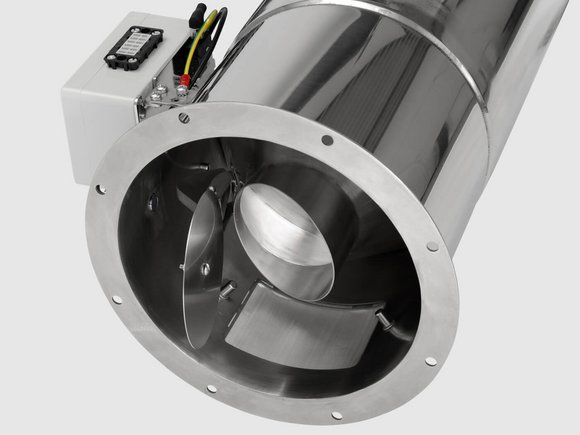

Material inlet flap

Optimum conveying capacity and minimum wear.The material loader inlet flaps make sure that multiple loaders can work together properly in a system. If several material loaders are connected via a coupling station, they limit the required vacuum. This design solution protects the material and ensures stable conveying performance without the need for check valves in the material flow at the coupling station.

The material loader inlet flap of the sCONVEY HOS is made of wear-resistant manganese steel to provide even better protection against wear from abrasive materials. A newly developed curved inlet flap design reduces the concentrated impact of the material on the inlet flap and loader body, thereby increasing the life of the hopper loader.

previous argument1 / 1next argument

×

Granules

sCONVEY HOS

Stable construction

Better stability of the hopper loader during operation.The two spring locks attached to the front and a hinge are arranged in a triangle and fixed at three points. This arrangement ensures greater stability of the hopper loader lid during operation. In addition, this ergonomic design facilitates the operator's handling by providing a safe and comfortable position.

previous argument1 / 1next argument

×

Granules

sCONVEY HOS

Sieve filter

Improved conveying capacity and dust collection.The sieve filter has a large surface area. The mesh size of the filter (1000μm) is suitable for efficient dust collection without removing any granulate.

previous argument1 / 1next argument

×

Granules

sCONVEY HOS

sCONMIX proportioning valve

Accurate and reliable addition and mixing of regrind and virgin materials.The polished stainless steel sCONMIX proportioning valve can be connected to the sCONVEY HOS material loaders. You can easily adjust the percentage and number of material layers per conveying cycle. A large transparent access panel gives you easy access for cleaning.

previous argument1 / 1next argument

×

Granules

sCONVEY HOS

Stainless steel discharge flap

Especially suitable for medical applications or food packaging.The stainless-steel discharge flap at the material outlet is abrasion resistant and meets all requirements for medical applications or food packaging. The angled design enlarges the outlet area, preventing material from bridging in the bin.

previous argument1 / 1next argument

×

Granules

sCONVEY HOS

Machine loader

Perfect for hygroscopic materials and where space is limited.When conveying hygroscopic materials with small throughputs or where space is limited a machine loader version is available. The unit must be mounted directly on the feed throat of the processing machine.

Integrated into the loader is a discharge flap which ensures a stable conveying and eliminates material being pulled during conveying from the processing screw of the moulding machine.

Your benefit is that no machine supply hopper is required, and very little material is stored at the machine. This is especially important for dried materials as the holding time of the material is kept to an absolute minimum.

previous argument1 / 1next argument

×

Granules

sCONVEY HOS

Loader control box

Designed for centralised system conveying applications.Easy to use control:

- On / off switch

- Plug connection to the conveying control

previous argument1 / 1next argument

×

Granules

sCONVEY HOS

Conveying control

Reliable and easy to handle.The microprocessor control with a 7" colour touch display is located at an ergonomically comfortable working height. 16 user languages can easily be selected. The alarm combination of signal light and horn is already installed as standard.

The following can be controlled with sCONVAC:

- up to 12 sCONVEY HOS hopper loaders

- up to 8 purging valves

previous argument1 / 1next argument