Injection moulding

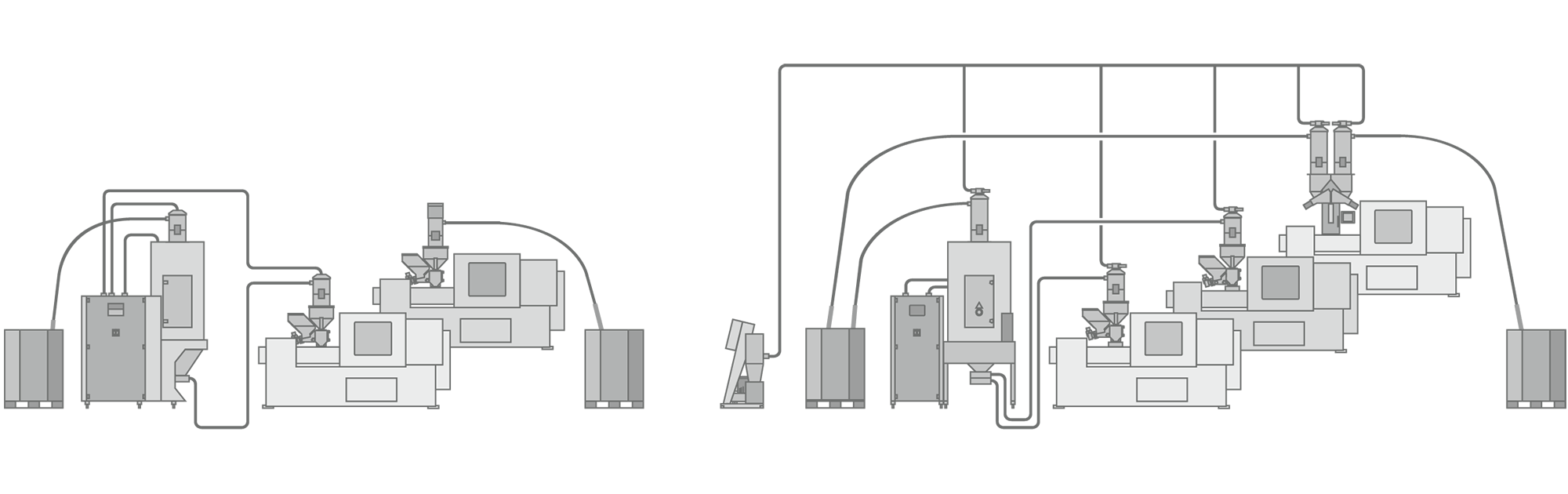

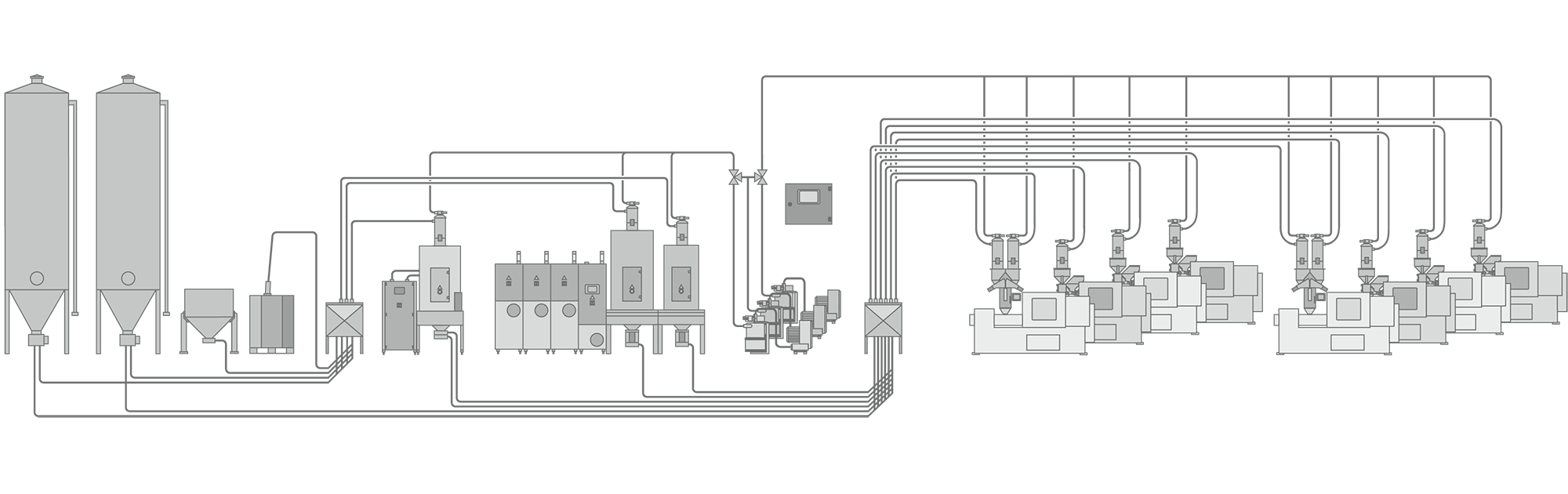

For everyday products. Central systems or individual units for branches such as automotive, electronics, household goods, etc.

For everyday products. Central systems or individual units for branches such as automotive, electronics, household goods, etc.

Injection moulding processes plastic into moulded parts. The process is discontinuous and has multiple steps. The material, usually a thermoplastic, is plasticized in a cylinder using a screw, mixed until it is homogenous, dosed, and then injected under high pressure into a mould, a so-called injection moulding tool. The material cools and hardens – the injection moulding tool is opened, and the moulded part is ejected.