Blow moulding

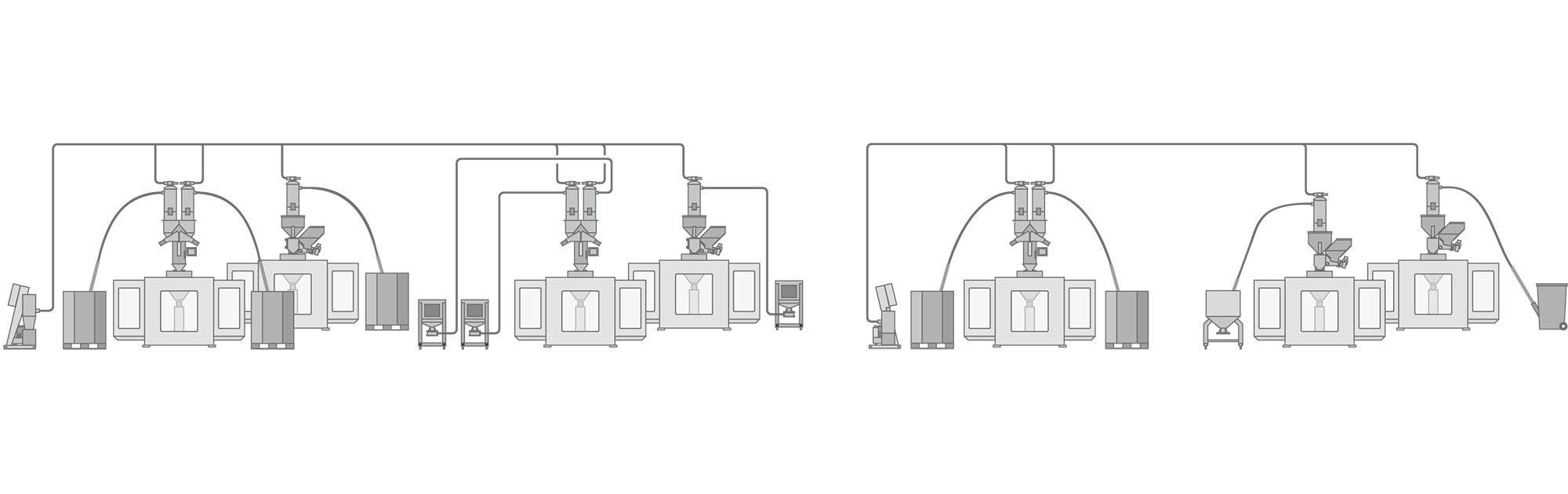

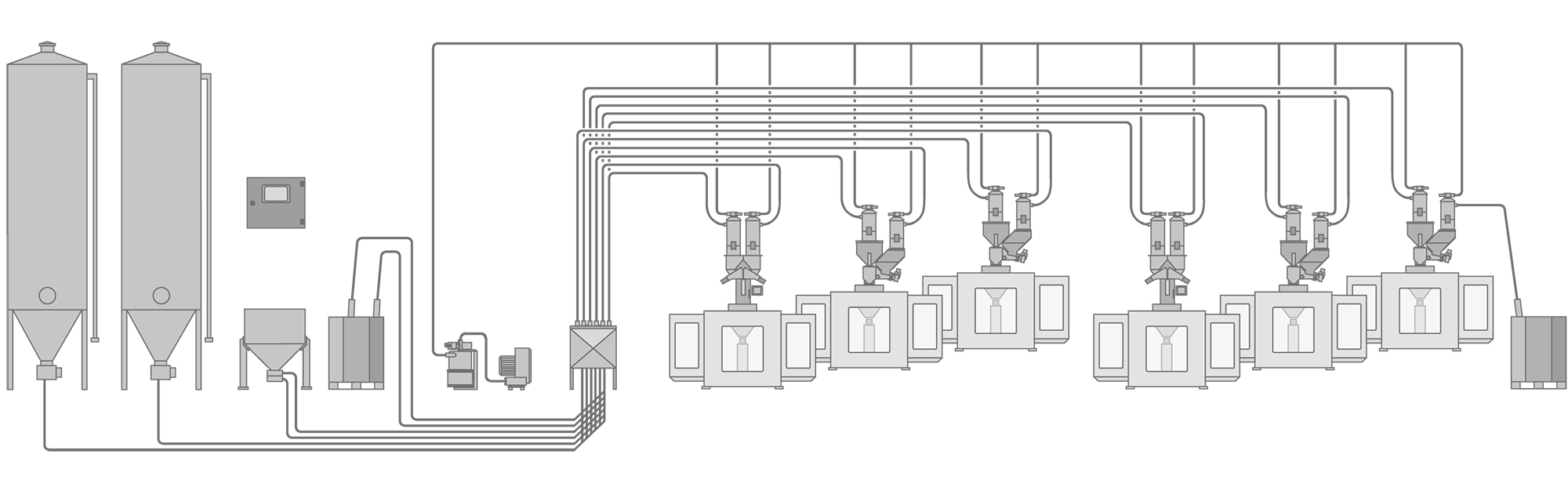

For bottles and containers. Reliable conveying, dosing & mixing systems for high-volume production of bottles and other containers.

For bottles and containers. Reliable conveying, dosing and mixing systems for high-volume production of bottles and other containers.

Blow moulding processes are used to make hollow parts from thermoplastics, such as containers, barrels, tanks, or bottles. Depending on the specific process, an injection moulded preform is manufactured, or a tube is extruded and, in a second inline step, is blown into a finished product using a mould. This us then cooled and ejected once it has hardened.