LUXOR CA A (8-60l)

Efficient, accurate material drying is a crucial element in the processing of engineering plastics to ensure impeccable product quality.

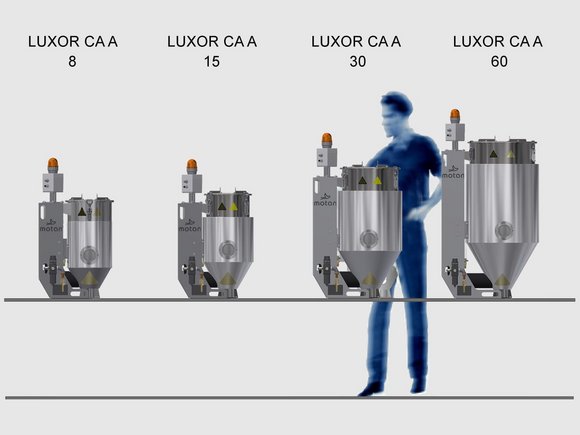

LUXOR CA A series compressed air dryers with ETA-process® and ETA plus® energy saving technology are specifically designed for supplying dried plastic granulate for many different plastics processing applications, with material throughputs up to 20 kg/h. Dryers can be mounted directly on the throat of the processing machine or on an adjacent support frame.

- ×

Dry air dryer

LUXOR CA A (8-60l)

Compressed air based dryers

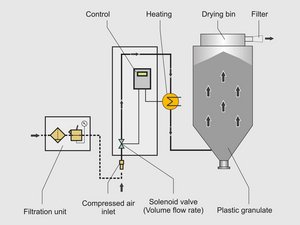

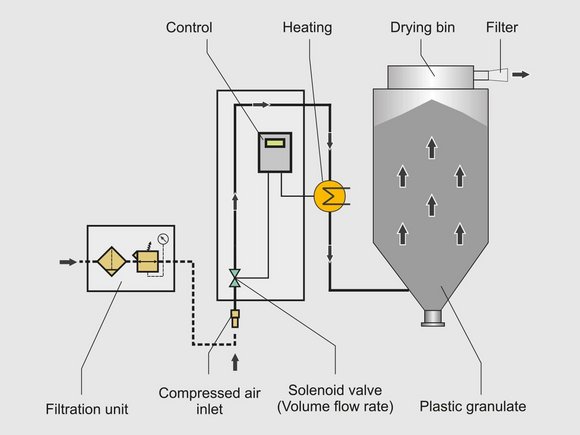

Contamination-free drying.The LUXOR CA A dryers take factory supplied compressed air which is expanded to atmospheric pressure. This produces dry process air with a very low dew-point which is then heated to the required drying temperature. No desiccant is required.

Dry air dryer

LUXOR CA A (8-60l)

ETA plus® technology

Innovative and energy efficient drying technology which saves you money.ETA plus® technology stands for innovative and energy-efficient drying technology which takes several individual factors into consideration:

- The air flow control receives a signal from the processing machine and so adapts automatically to the amount of material being dried.

- Once the air flow has been reduced to its minimum value, the drying temperature adapts automatically to the amount of material being dried. This guarantees very gentle drying, especially when there is a large drop in material throughput rates.

Dry air dryer

LUXOR CA A (8-60l)

Maintenance-free

No moving parts. No desiccant material.No moving parts, no desiccant material. LUXOR CA A will deliver the reliable performance you need.

Dry air dryer

LUXOR CA A (8-60l)

Optimal process air

Always the right temperature and quality.Due to the wide temperature range (30 - 180°C), the LUXOR CA A dryers can be used for many different materials. A pre-filter cleans the compressed air. This prevents contamination of the raw material and provides optimum drying conditions.

Dry air dryer

LUXOR CA A (8-60l)

Small construction

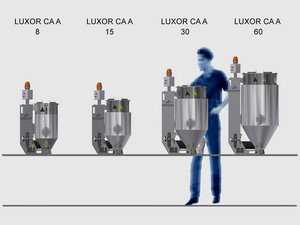

Meets the small tolerances with no waste.The LUXOR CA A dryers have been specially designed for small to medium material throughputs, with drying bin volumes ranging from 8 litres to 60 litres. A modular set of correctly sized drying equipment helps you to meet the small tolerances without waste or contamination.

Dry air dryer

LUXOR CA A (8-60l)

Stainless steel construction

Designed for reliability and a long lifeThe complete drying bin body is made from stainless steel. This is ideal for contamination critical process applications.

Dry air dryer

LUXOR CA A (8-60l)

Energy-saving drying bin

Saving your energyThe drying bin as well as to the material discharge cone is heat insulated and thus guarantees stable conditions in the bin. The intelligent control removes only the compressed air you need. When the machine stops, the dryer goes into “dry hold” mode. Saving energy.

Dry air dryer

LUXOR CA A (8-60l)

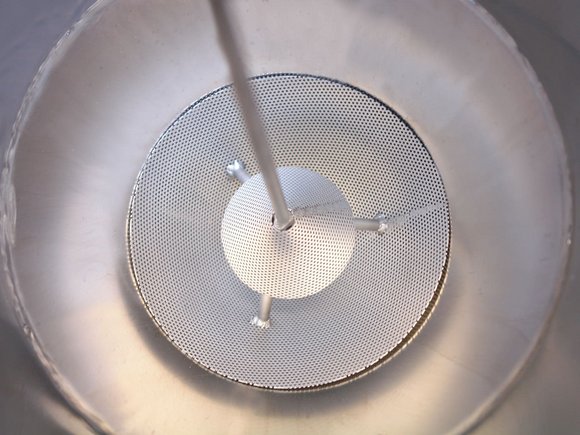

Air diffuser

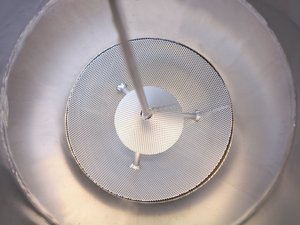

Uniform distribution of dry air, guaranteeing your material is at temperature and dry.The cleverly designed air diffuser provides uniform distribution of the dry air ensuring that even material at the material bin outlet is kept dry and at a constant temperature.

Dry air dryer

LUXOR CA A (8-60l)

Design

Built for reliability and long life.All models are equipped with thermostat and low-air-flow safety switch to prevent overheating of material. The hinged lid of the drying bin provides easy access and has a flange for fitting a METRO material loader for automatic material conveying.

Dry air dryer

LUXOR CA A (8-60l)

Drying bin geometry

Essential for correctly dried material.The ratio between the height and diameter of a drying bin is critical to how a material flows through the bin. Incorrect mass flow can lead to “dead” corners where the material is over dried or the material will flow too quickly through the middle of the bin resulting in under dried material.

The optimum dimensions of the cylindrical drying bins are determined by calculation and practical tests, guaranteeing correctly dried material is delivered to your processing machine.

Dry air dryer

LUXOR CA A (8-60l)

LUXORnet CA A

State-of-the-art control with innovative, Ethernet-based open network architectureThe LUXORnet CA A control offers user-friendly operation via a colour graphic display with touch screen. LUXORnet CA A incorporates comprehensive functions for operation and process control, recipe management, reporting for quality assurance, as well as enhanced service functions and trend charts. ETA plus® airflow control with temperature adaptation is available as standard.

To simplify the input of the material-related drying parameters such as drying time and temperature, a material database is integrated in the control. The database includes a data pool with parameters for about 70 standard materials and can accommodate up to 100 data sets as specified by the customer.

The control utilises modern, flexible Bus technology and can manage up to 8 LUXOR CA A compressed air dryers.

LUXORnet technology stands out due to its modern, Ethernet-based open network architecture enabling standard networking with all other motan CONTROLnet controls.

Dry air dryer

LUXOR CA A (8-60l)

METRO VL compressed air loader

Maintenance free, silent and wear-free in operation.The drying bin can be filled reliably and automatically with the METRO VL compressed air venturi loader. It is virtually maintenance free and silent.