METRO SG HES

The METRO SG HES range of single-phase material loaders enable processors to automate a key area of the production process cost effectively, bringing significant benefits for process management.

Plastic granulate is conveyed quickly and cleanly to a processing machine hopper, a drying bin or a day bin as needed.

The material loader is equipped with its own control, so that it recognizes when material is needed and automatically starts conveying. This keeps machines running and avoids costly downtime while eliminating material wastage, keeping the workspace clean and safe.

The METRO SG HES range can handle throughputs of 15 to 200 kg/h.

- ×

Granules

METRO SG HES

Optimized noise insulation

Quiet in operationAll METRO SG HES loaders are equipped with specially insulated hoods which dramatically reduce the noise of the single-phase conveying motors.

Granules

METRO SG HES

Brushless motor

Maintenance and wear freeThe METRO SG HES 200 model is equipped with a reliable brushless motor and soft-start for wear-free operation.

Granules

METRO SG HES

Hinged lid

Easy to cleanAll METRO SG HES loaders have a hinged lid for easy cleaning of the loader and the filter. The hood can be lifted back without the need of tools for quick material changes.

Granules

METRO SG HES

Filter cleaning

Guarantees constant and stable material conveying and reduces maintenance costsThe filter is automatically cleaned by compressed air after every conveying cycle. This guarantees constant and reliable material conveying and reduces maintenance costs for the loader.

Because the material loader is air-tight, the conveying performance remains stable and there is no dust around the unit.

Granules

METRO SG HES

Filter cartridge instead of cloth filter

Defined filter classA filter cartridge for dust class M is available for the METRO SG HES 50 / 80 / 200 models.

This can alternatively be built into the unit for a more precise degree of separation.

Granules

METRO SG HES

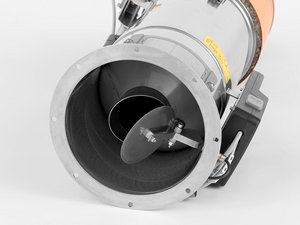

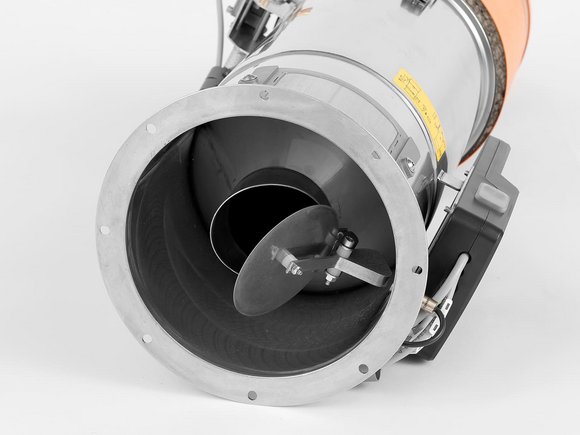

Stainless steel discharge flap

Abrasion resistantBecause the large material outlet has a discharge flap which is made of stainless steel, it is abrasion resistant and meets all requirements for medical or food packaging applications. The angled design increases the outlet area and helps with materials which may bridge.

Granules

METRO SG HES

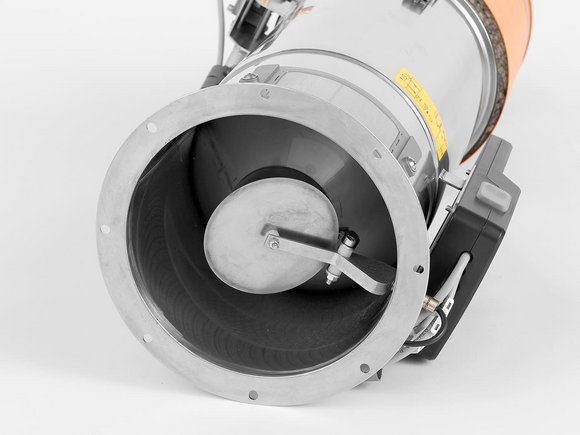

Polished stainless steel

Contamination free and easy to cleanAll material loaders are modular and are constructed using polished stainless steel, guaranteeing you contamination-free operation and easy cleaning due to the high-quality surface finish.

Granules

METRO SG HES

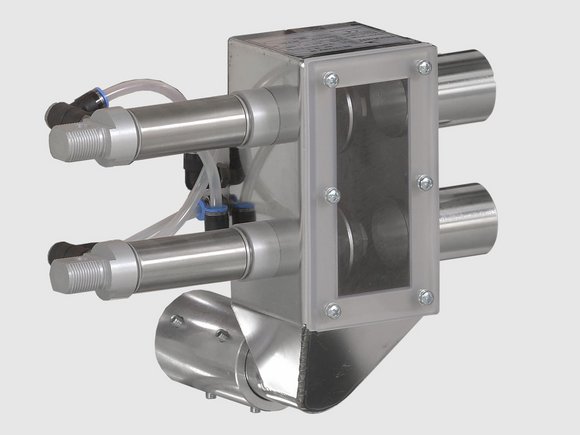

METROMIX proportioning valve

Accurate and reliable addition and mixing of regrind and virgin materialsThe control of the METROMIX proportioning valve is already integrated into the METRO SG HES loader control. You can easily adjust the percentage and number of material layers per conveying cycle using the keypad.

A large transparent access panel gives you easy access for cleaning.

Granules

METRO SG HES

Line purging

Ensuring correctly conditioned material is delivered to the machineThe METRO SG HES control has an integrated line purging function. When connected with a motan purging suction box, the material feedline can be cleared of any material after every conveying cycle. This is essential for the conveying of hygroscopic materials and for fast and trouble-free material changes.

Granules

METRO SG HES

Granulator delay

Delay of start-upWith the “granulator delay” function, the start-up process can be delayed. The loader will not immediately start even if the supply signal has been received from the sensor, allowing for the granulator suction box to fill up with a specific amount of material first. This prevents the need to constantly be switching the loader on and off, saving energy costs.

Granules

METRO SG HES

Control

With new ALARM LED-ringEasily operated control:

- All functions can be operated on the plastic film keypad

- Alarm display on top of unit with LED ring

- 7-segment LED display for set value/actual value display as well as parameters in configuration mode

- Illuminated symbols for status display

- Program selection – purge function or filter cleaning before and/or after conveying

Pre-alarm after 5 conveying attempts, STOP after 50 false conveys or suppression of STOP